SANBOR HDPE Corrugated Pipes and Fittings are produced in the diameter range of Ø 100-1000 mm with extrusion corrugator molding technology and double-layered from high density polyethylene (HDPE) raw material. In recent years, the use of corrugated pipes is rapidly becoming widespread due to their resistance to chemical substances formed in the pipeline or produced from the environment and transferred to the system, long life, ease of installation, maintenance and repair, compliance with environmental protection with the sealing provided and high strength.

RELEVANT STANDARDS AND TEST METHODS

- SANBOR Corrugated Pipes and Fittings, produced as double-walled from high density (HDPE) polyethylene, are produced according to TS EN 13476-3+A1 standard.

- Corrugated Pipe gaskets used in the system comply with EN 681 standard.

- Leakage tests of the laid pipe system are carried out according to EN 1610 standard.

USAGE AREAS

- In sewage wastewater removal lines,

- In urban and domestic waste water removal lines,

- In rain and snow water transport and discharge lines,

- In drainage and ground water transport lines,

- Industrial and industrial wastewater transport systems,

- Gravity liquid transportation systems that do not require pressure,

- Chemical and biological waste transportation systems,

- Energy-communication cable protection systems

ADVANTAGES OF CORRUGATED PIPES

- Since it adapts to ground movements due to its flexible feature, it can be used against earthquakes, traffic loads, etc. They are not adversely affected by ground movements.

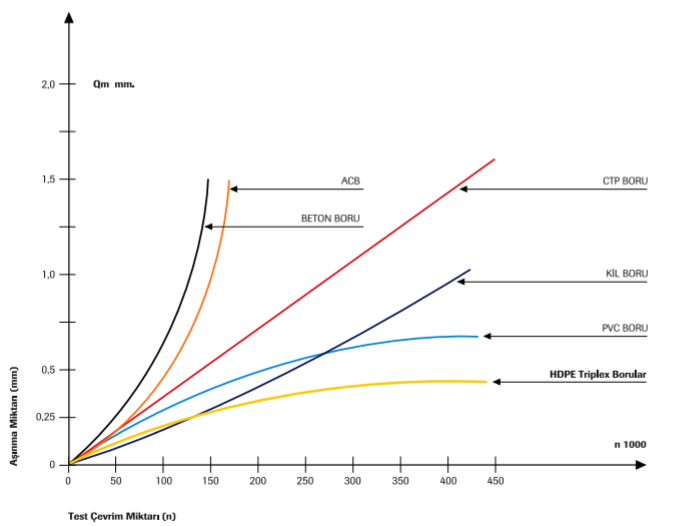

- Since corrugated pipes are combined with the sleeve - elastomeric gasket connection method, they provide sealing at the pressure value (0.5 bar) specified in the relevant standards. In this way, it helps protect nature by being environmentally friendly.

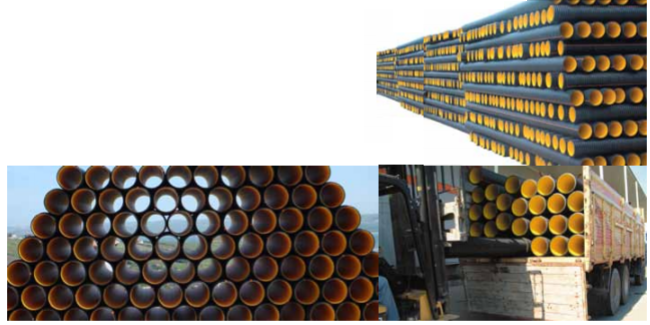

- Thanks to its light weight and ease of assembly, there is no need for heavy equipment when laying pipes up to DN300.

- The inner surfaces of corrugated pipes are manufactured in light color (yellow), allowing them to be monitored with a camera.

- The outer surface is black with UV additive and is not affected by sunlight.

- It is resistant to temperature changes.

- It is produced from 100% recyclable material and is environmentally friendly.

- The lifespan of corrugated pipes is at least 50 years.

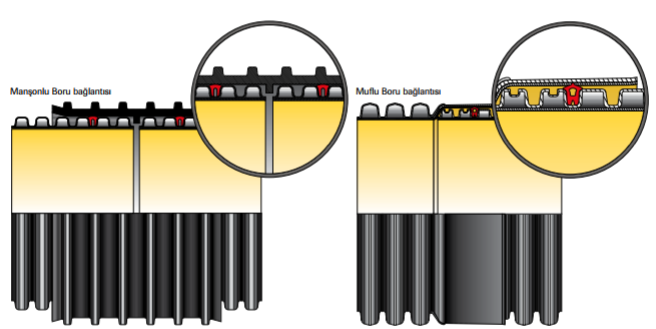

- SANBOR Corrugated pipes provide ease and economy in transportation and stacking due to their lightness. By placing them inside each other, telescopic storage and transportation can be done.

- The fact that the inner surfaces are less rough than other materials ensures laminar flow by reducing the friction surface of the fluid and also eliminates the risk of cut narrowing.

- Thanks to its sealing feature, it prevents the wastewater inside from polluting our underground water resources.

High Ring Stiffness and External Load Resistance

In sewer systems, there is usually non-pressurized (free) flow. Therefore, the effect of external loads such as soil and traffic load is important. SANBOR Corrugated Pipes show high resistance to heavy soil and traffic loads with their specially designed cross-section and ribbed body structure. Due to the molecular structure of the polyethylene raw material, the flexibility of corrugated pipes is quite high. Since they are elastic, they are not affected by seismic ground motion and do not deform. They absorb the loads by undergoing elastic deformation in the face of sudden load shocks and return to their previous form. The permanent deformation limit can be up to 7.5%. While deformations at these values cause breakages and deteriorations in many different pipe systems, no problems occur in SANBOR Corrugated Pipes.

High Wear Resistance

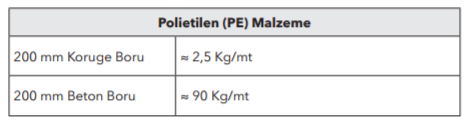

HDPE is the material with the highest abrasion resistance among known plastic-based raw materials. HDPE's high resistance to abrasion has been documented as a result of research tests conducted by the University of Darmstadt, Germany. As a result of approximately 100,000 test cycles, it has been seen that the wear on HDPE samples is at the lowest level compared to other materials.

Long Working Life

SANBOR Corrugated pipes have a minimum lifespan of 50 years thanks to their resistance to corrosion, high abrasion and chemical resistance, flexibility that is not affected by shocks, resistance to temperatures up to 60 C, and maintenance-free system structure. It does not require maintenance for many years.

High Chemical Resistance

SANBOR Corrugated Pipes are produced from Polyethylene raw material, which has very high resistance to chemicals. In sewer lines, there is usually a flow pattern that is gravity, unpressurized and not fully filled. Acid vapor released by solid and liquid wastes such as acid-containing liquids and highly concentrated salts causes corrosion around the pipe, negatively affecting the working life of the pipe. They cause serious deterioration in the structure of the pipes, especially by causing abrasion and dissolution on the inner surface of concrete and metal pipes. Thanks to its excellent resistance to chemicals, wear and corrosion problems do not occur on the inner surfaces of Sanbor Corrugated Pipes.

High Flow Performance

SANBOR Corrugated Pipes provide high fluidity speed with their low friction coefficient and smooth structure of their inner surfaces. Thanks to the smooth inner surfaces of Sanbor Corrugated pipes, which resemble the glass surface, solid particles do not stick and form residue and debris. Thus, the inner wall of the pipe remains open at all times. Since Sanbor Corrugated Pipes provide very high flow performance, it is possible to obtain a smooth and controlled flow even in pipes of lower diameter.

100% Leak Proof

SANBOR Corrugated Pipes and Fittings are designed and manufactured to meet all kinds of needs in the application field. SANBOR Corrugated Pipes and Fittings are joined by the gasketed fitting method. Designed in accordance with EN 681 standards and all kinds of risk possibilities, Corrugated Pipe seals do not leak throughout the life of the pipe and prevent wastewater from mixing with groundwater and soil. In addition, in places with high ground water, external water entry into the sewer system is prevented. This prevents the line from overfilling and overflowing.

Easy assembling

SANBOR Corrugated pipes are combined with bells and gaskets. Connection can be made easily in any construction site environment. Since corrugated pipe is light, there is no need for heavy equipment during laying. Electricity, welding machine, adhesive etc. Does not require equipment.

Production in Desired Length

Corrugated pipes are produced in standard 6 m lengths. Pipes without bellhousing can be produced in any length according to customer demand.

Ease of Transport and Stacking

Since SANBOR Corrugated Pipes are light and have high impact resistance, it is possible to transport and store them by telescopic and stacking them on top of each other.

Since Corrugated Pipes can be stacked from large to small diameters, serious cost advantages are provided in space, time, transportation and storage.

Thanks to the variety of additional parts, even the shortest parts can be used, so there is no wastage during assembly.

Since SANBOR corrugated pipes are light and impact resistant, there is no wastage due to impacts and falls that may occur during transportation and storage.

.

TESTS APPLIED TO CORRUGATED PIPES

| Test Adı |

Test Metodu |

Birim |

Test Sonucu |

| Density Test |

EN ISO 1183 |

kg/m3 |

≥ 930 |

| Melft Flow Index |

EN ISO 1133 |

gr./10 min |

≤ 1.6 |

| Heat Test |

EN ISO 2505 |

- |

Proper |

| Ring Flexibility |

EN ISO 13968 |

- |

Proper |

| Circle Stiffness |

EN ISO 9969 |

kN/m2 |

≥ Sn |

| Crush Resistance |

EN 744 |

- |

Proper |

| Leak Tightness Test (0,5 bar 15 dak.) |

EN 1053 |

- |

No Leakage |

| Thermal Stability(OIT) (200ºC de) |

EN ISO 11357-6 |

min |

≥ 20 |

Ring Hardness (SN)

SANBOR Corrugated Pipes provide the SN (ring hardness) value prescribed by TS EN 13476-3 standard, SN4 and SN8 values when tested in accordance with the ISO 9969 standard to which this standard refers.

Ring Elasticity

SANBOR Corrugated Pipes are made in accordance with the EN ISO 13968 standard. With the pressure applied to the outer diameter of the pipe, it is stretched by 30% of the pipe diameter, and as a result, there is no cracking, breaking or deformation in the pipe.

Impact Resistance

When SANBOR Corrugated Pipes are tested in accordance with the EN 744 standard, the pipes can withstand the pipe samples conditioned at 0°C without breaking when the weight appropriate to each diameter specified in the relevant standard is applied to the pipe in free fall.

Leak Tightness Test

The system, consisting of elastomeric sealing ring pipes and fittings made in accordance with the EN 1053 standard, can withstand leakage when tested with 0.5 bar of water for 15 minutes.

CORRUGATED PIPE MATERIAL SPECIFICATIONS

| Özellikler |

Test Conditions |

Unit |

Test Method |

Test Result |

| Density |

23ºC |

g/cm3 |

EN ISO 1183 |

≥ 0.930 |

| Melt Flow Index MFI |

190ºC, 5 kg |

g/10 min |

EN ISO 1133 |

≤ 1.6 |

| Elasticity Module |

23ºC, 1 mm/min |

Mpa |

ISO 527 |

≥ 800 |

| Thermal Stability |

200ºC |

min |

ISO 11357-6 |

≥ 20 |

| Vicat Softening Temperature |

10N |

ºC |

EN ISO 306 |

125 – 135 |

LOADING QUANTITIES

| Diameter |

100 mm |

150 mm |

200 mm |

300 mm |

400 mm |

500 mm |

600 mm |

800 mm |

1000 mm |

| Semi-Truck |

550 |

230 |

125 |

64 |

34 |

20 |

12 |

8 |

2 |

| Truck |

1000 |

460 |

250 |

128 |

68 |

40 |

24 |

16 |

4 |